Blogs | Dawn Journal | July 29, 2006

July 2006

Dear Dawnthusiasts,

Dawn continues to keep its human handlers very busy as preparations continue on schedule to meet the planned opening of the launch period on June 20, 2007.

Much of June 2006 was devoted to conducting the comprehensive performance tests (CPTs) described in the previous log. In these tests, most of the hardware and software subsystems already on the spacecraft were exercised to help uncover problems ranging from incomplete solder connections on a microchip or a broken wire, to software bugs, to unexpected interactions between subsystems that must work together. Of course, each subsystem was tested extensively as it was being built, but some afflictions may remain hidden until the subsystem is operating on the spacecraft with other subsystems. As thorough as the CPTs are, testing will become more and more demanding over the coming months as the spacecraft is asked to perform in ways progressively more like what it will encounter during its voyage to the asteroid belt and its explorations of Ceres and Vesta, the most massive bodies in that region of the solar system. The upcoming tests will be described in future logs.

The CPTs yield a tremendous volume of data, and engineers are still analyzing the details of their subsystems' performance, but all indications are that the tests went extremely well. As our humble human readers know, some errors are inevitable in a design as intricate and complex as one of Earth's interplanetary spacecraft. So far it appears that all such flaws are easily correctable.

Some subsystems have not yet had their first CPT. The ion propulsion subsystem and the instruments for collecting scientific data are awaiting their tests in August. We will introduce each of Dawn's subsystems in the next log.

Some of the ion propulsion subsystem's individual components received some extra testing recently before being mated to the spacecraft in June. The power processing units have to provide the properly controlled voltages and currents to different elements of the ion thrusters, which apply the electrical power to xenon gas to produce fantastically efficient propulsion, without which Dawn's ambitious mission would be quite impossible. Each unit will process up to 2500 watts (much more than the average house consumes), and we wanted special assurance that these devices would perform reliably on the mission. So in addition to the testing they received at the company that manufactured them for Dawn, each one was subjected to further trials in one of JPL's laboratories. The devices were operated for about 20 days in vacuum chambers. During most of that time, the units were pushed to the highest temperature they will experience on the spacecraft of 35°C (95°F). Both units passed with flying colors (what other kind of colors would you expect for space hardware?), adding to the confidence that they are up to the rigors of Dawn's mission.

While operating in their thermal vacuum chambers, the power processing units were under the control of the same software that runs in the ion propulsion control unit on the spacecraft. So this work provided a bonus opportunity to test the software that operates this complex subsystem on its travels through deep space.

Each of the three ion thrusters will be mounted on a mechanism that allows its pointing direction to be fine-tuned by other software on the spacecraft. As we will see in the next log, this accurate aiming is essential, so if one of these mechanisms fails, the attached thruster would be useless. To verify the robustness of the design for the mechanism, a test unit was subjected to 10 times the amount of work the ones to be flown on Dawn will have to provide. The performance was flawless.

After the ion propulsion subsystem testing and the first set of CPTs were completed in June, the focus of the Dawn team's activity in July was on what nontechnical readers might think of as baking the spacecraft. The technical term used by the engineering team was -- well, baking out the spacecraft. This was not a test; rather, bake-out was intended to heat the spacecraft to drive off contaminants it might have collected, despite the assembly having been conducted in a specially controlled "clean room" at Orbital Sciences Corporation.

The first step in the bake-out was to clean the oven in which the baking would occur, a cylinder 3.7 meters high and 4.9 meters long. (Ever poetic, team members fondly refer to this facility as the "12 by 16 foot chamber.") For several days, the chamber was heated to 95°C (203°F). This ensured that its interior would be free of chemical residue that might contaminate Dawn.

With the chamber certified to be clean, the spacecraft was moved in. As it is not completely assembled yet, some of the flight equipment was simply placed in the chamber with the spacecraft. After the chamber was sealed, it took 7 hours to reduce the pressure to about 100 million times lower than atmospheric pressure. Then the temperature was raised gradually over more than a day and a half to bring the spacecraft to a toasty 53°C (127°F). As with most other details of the design, assembly, test, and operations in flight, the temperature was selected after a substantial amount of careful analysis. It had to be high enough to force the contaminants off in a reasonable amount of time without the heat endangering the spacecraft. As Dawn will go farther from the hot Sun than Earth is, accommodating very high temperatures was not among its design criteria.

Accompanying the flight hardware in the chamber were sensors to allow the operators to monitor temperatures, and team members babysat the spacecraft around the clock to ensure its safety. Contamination monitors permitted the operators to observe the rate at which material was being driven from the spacecraft, and the bake-out was scheduled to continue until the rates reached a predetermined low value. Although it had been expected this would require nearly a week of baking, it turned out to require less than two days at the maximum temperature. The team was pleased to conclude that the spacecraft must have started out cleaner than had been anticipated.

In addition to the sensors that provided feedback during the bake-out, other contamination monitors were included that will be analyzed in laboratories to understand more about the kinds of contaminants that were present. Ultraclean silicon wafers were intended to collect tiny fibers, many times thinner than human hair, and aluminum plates can reveal evidence of films just a few molecules thick.

Both before and after the bake-out, the spacecraft was inspected carefully under illumination with ultraviolet light and separately with old-fashioned (but still effective!) visible light. Such inspections will be repeated many more times before launch. Any debris that is found is removed with a brush and small vacuum or with special materials soaked with purified alcohol. As one might imagine, using an inspector's thumb or the corner of his T-shirt to wipe off unwanted material is not part of such a delicate procedure.

While the careful assembly and demanding testing of the spacecraft continues, there remains one piece of essential hardware that will not even begin fabrication until late this year. It is not needed for Dawn to carry out its assignment to explore alien worlds and to reveal clues to the dawn of the solar system, but it is a vital ingredient in another aspect of Dawn's mission. And despite the engineering and scientific breadth and depth of the Dawn team, this component is beyond our means to produce without the help of hundreds of thousands of people, including you, dear reader.

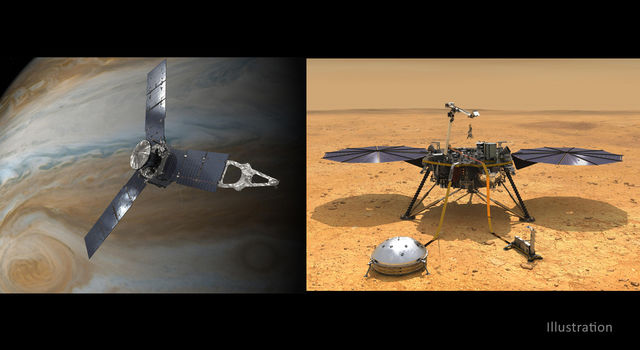

In many ways, we are still in the early stages of humankind's journeys through the solar system. This is evident when we recognize that Dawn is the first spacecraft designed to orbit a target in the main asteroid belt. This vast region of space has been traversed by a few probes that were flung from the inner solar system to reach the outer solar system, but no spacecraft has yet been assigned to stop there and develop an intimate portrait of some of the residents. Indeed, until Dawn, with its ion propulsion system, no spacecraft has had such a capability.

As other explorers, Dawn's mission is about more than seeing what is out there and helping us unravel secrets of the cosmos. Dawn carries with it the spirit of those it represents on its homeworld: a yearning to extend beyond the bounds of our terrestrial experience, a grand quest for ever greater knowledge, an irrepressible drive to understand how our celestial neighborhood fits together in space and time. Missions like Dawn's help fuel the passionate and noble fires that burn in the hearts and minds of people everywhere. It is these shared feelings that make this more than simply another attempt to record scientific data.

To emphasize the nature of this joint participation in the mission and make it more real, more rewarding, and more personal, we invite you to include your name on the spacecraft. Later this year, we will fabricate a chip to be carried on the spacecraft, imprinted with the name of each person who wishes to have a part in this collective adventure of humankind. While the Dawn project can make the chip, it would mean nothing without all the names.

So be among the first on your planet to submit your name by going to http://www.dawn-mission.org/DawnCommunity/Sendname2asteroid/nameEntry.asp.

Dr. Marc D. Rayman

July 29, 2006

TAGS:DAWN, VESTA, CERES, DWARF PLANET, MISSION, SPACECRAFT